A sophisticated new laboratory workstation at St. Paul’s Hospital is using artificial intelligence and robots for repetitive tasks to let humans do the complex work.

And although some of the components of this new $1-million WASPLab might be new, they’re already paying dividends.

The dynamic robot duo of “Tarzan” and “Jane” handle and process up to 70 per cent of laboratory samples that come through St. Paul’s Hospital Microbiology Laboratory these days, just a glimpse of the future at the new hospital. The pair is part of the new WASPLab funded by a donor from St. Paul’s Foundation. It’s highly efficient, modular, and scalable; it also frees up staff to focus on essential patient care tasks, while improving overall laboratory quality and efficiency.

“Ultimately, in order to optimize patient care, we want technologists to concentrate on the more complicated analytical laboratory work, the more interpretive work that requires human thought; we don’t want technologists to be performing manual work that machines and robots can easily take on,” says Dr. Marc Romney, Head of Medical Microbiology and Virology.

At the new St. Paul’s Hospital, two of these workstations – including the current one – will be fully operational.

“This type of fully automated system that includes robotics, conveyance and AI is an integral part of how the new St. Paul’s Hospital is achieving its goal of being the most technology-enabled hospital in the province,” says Janice Bittante, Clinical Lead for the project team. “The spirit of innovation the laboratory staff bring to this project always amazes me and makes this work so exciting and rewarding.”

Improving patient care and staff wellness

Automation is a welcome addition at a busy laboratory like St. Paul’s Hospital, which processes over 145,000 microbiological samples each year from BC and the Yukon. The team of doctors and laboratory staff spent many months working with the Italian manufacturer, Copan, to help customize the new automated workstation to meet the lab’s needs.

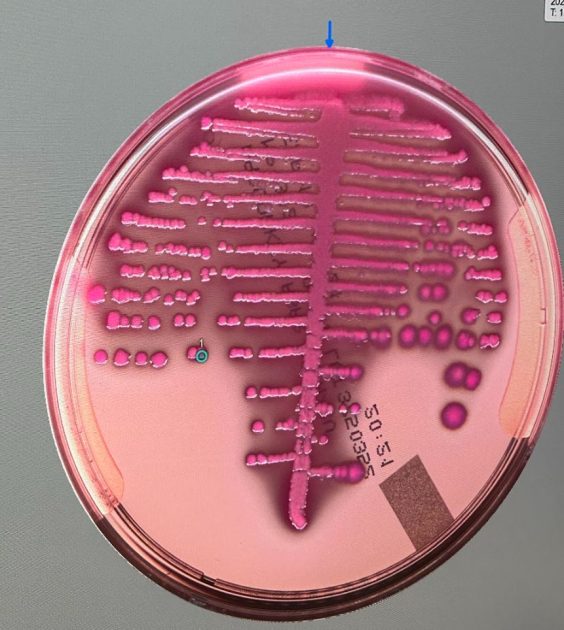

For example, WASPLab uses standardized techniques to streak plates and capture individual colonies of bacteria, processes which would otherwise have been done by staff.

“Some patient specimens, especially those from the Yukon, come in late in the evening when laboratory staffing levels are typically lower,” says Willson Jang, team lead of Microbiology and Virology. “Before the WASPLab, those samples would have had to wait until the next morning. Now, technologists can put the bulk of them onto the WASPLab while they’re performing other important tasks. It’s been a huge benefit and has helped us deliver results faster so clinicians can start treating patients sooner.”

It’s also been better for staff’s physical well-being, says Dr. Romney.

“A lot of the work this machine does is repetitive and manual, like unscrewing the tops of specimen collection tubes, which requires a lot of hand dexterity and wrist work. All this manual work can cause repetitive strain injuries resulting in things like carpal tunnel syndrome. We want to focus on preserving the health and safety of our laboratory staff as much as possible.”

Leading the way in Western Canada

While laboratory automation is not new, what makes St. Paul’s WASPLab unique in Western Canada is the integration of advanced artificial intelligence (AI) with digital images and automation. The workstation can automatically pre-assess and pre-sort culture plates, segregate bacterial cultures, and alert lab staff when results need further analysis.

The machine also features sophisticated digital technology to capture high-quality images of culture plates, which makes it easier for staff to review and analyze.

When the new St. Paul’s Hospital opens in 2027, Dr. Romney estimates up to 85 per cent of the laboratory’s clinical specimens will be processed by the two WASPLab workstations.

“At the new St. Paul’s Hospital, AI will be performing some of the simpler tasks that are now assigned to technologists, and as it matures, AI will become more sophisticated and impactful,” says Dr. Romney. “However, there will always be a need for critical thinking and careful analysis of test results, and also supervision of the instruments. Fortunately, there will always be a need for humans in the laboratory!”

Story by Justine Ma, Senior Communications and Engagement Specialist